For textile businesses and apparel brands, the Direct-to-Film (DTF) process has become a game-changer due to its versatility and high-quality output. Unlike traditional screen printing, a digital textile printer allows you to move from a digital file to a finished garment with remarkable speed. But how does this technology actually bond a design to fabric?

The Core Stages of the DTF Workflow

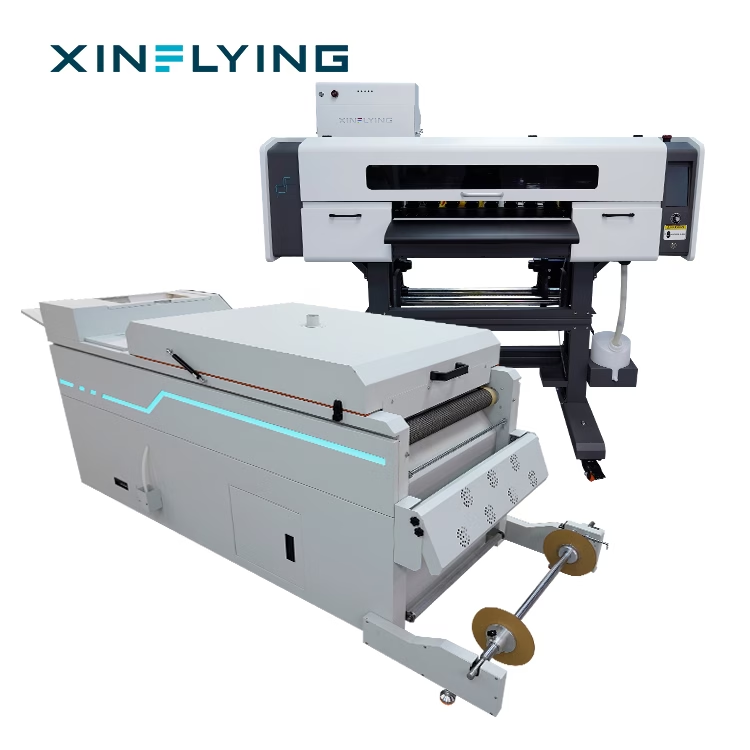

As a specialized DTF printer manufacturer, Xinflying designs systems that automate many of these steps, ensuring consistency for industrial-scale production.

Digital Printing: The design is sent to the printer via RIP software. The machine prints the CMYK color layer first, followed by a white ink layer.

Powder Application: While the ink is still wet, a hot-melt adhesive powder is applied. In a professional Xinflying setup, an integrated shaker ensures the powder is distributed evenly and excess is removed.

Curing: The film passes through a curing oven (typically at 160°C) to melt the powder into a specialized adhesive.

Heat Transfer: The cured film is placed on the fabric and pressed. The heat activates the adhesive, bonding the ink directly into the textile fibers.

Peeling and Finishing: After cooling (for cold-peel film), the PET film is removed, leaving a vibrant, stretchable design.

Industrial Spotlight: The Xinflying 704E+Z60L4

For high-volume manufacturers, the 704E+Z60L4 24-inch DTF Printer is a top-tier choice that streamlines these steps with industrial stability.

Technical Specifications:

Production Capacity: High-efficiency printing reaching up to 27m²/h (4-pass).

Printhead Array: Equipped with 4pcs Epson i3200-A1 printheads for sharp resolution and long-term durability.

Precision Engineering: Features an imported mute rail for stable, noise-free carriage movement.

Automated Maintenance: Built with a white ink circulation system to prevent clogging, which is critical for maintaining high-opacity white bases.

By partnering with a trusted DTF printer manufacturer like Xinflying, businesses can master the DTF process to deliver wash-resistant, professional-grade apparel on nearly any substrate, from cotton and polyester to leather and nylon.