Plastic manufacturing projects often begin with one practical question: how much does injection molding plastic cost in China? For international buyers sourcing through China injection molding, the answer depends on more than a single price figure. Tooling complexity, material choice, and production scale all influence cost structure. Companies like Livepoint Tooling operate within this environment by focusing on precision tooling and stable manufacturing processes rather than short-term pricing strategies. From the earliest design stage, they approach cost control as part of engineering planning instead of treating it as a final negotiation step.

Tooling Design and Precision Mold Complexity

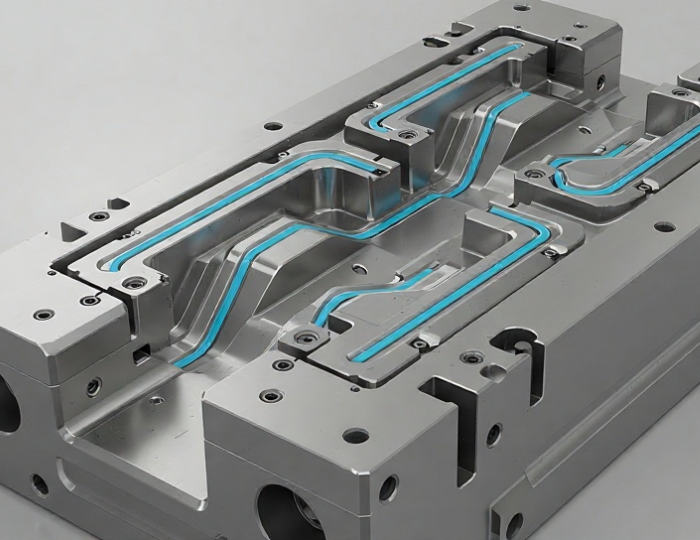

A significant portion of plastic injection molding cost in China comes from mold development. Precision molds require tighter tolerances, refined steel selection, and longer machining cycles. This is especially relevant for components used in electronics, automotive interiors, or medical housings. When working with a China injection molding supplier, buyers often find that tooling cost varies based on part geometry, expected lifespan, and surface finish requirements.

Livepoint Tooling structures its tooling workflow around design-for-manufacturing principles, which helps reduce rework and trial adjustments. Their experience with precision molds allows them to balance tooling durability with production efficiency. This approach helps stabilize long-term project cost, especially for programs that move from small batch runs into sustained production.

Material Selection and Process Efficiency

Material choice plays an equally important role in determining injection molding cost. Standard thermoplastics are typically easier to process, while engineering plastics may require higher temperatures, controlled cooling, and specialized mold features. In China injection molding, process efficiency is often tied to how well the mold design matches the selected material.

Overmolding can improve grip, insulation, comfort, or protective performance, but it requires accurate mold alignment and controlled bonding conditions. When applied correctly, overmolding can reduce assembly steps and overall part count, helping offset additional tooling investment through streamlined production.

Production Volume, Lead Time, and Quality Control

Beyond tooling and materials, production scale influences unit pricing. Low-volume runs typically carry higher per-part costs due to setup and validation time, while stable volume production allows costs to normalize. A reliable China injection molding supplier usually focuses on maintaining consistent cycle times, controlled scrap rates, and predictable lead schedules.

Livepoint Tooling integrates quality checks throughout molding and post-processing stages, rather than relying solely on final inspection. This reduces variation during extended production and supports efficient delivery without unnecessary delays. Their emphasis on process control aligns with projects that require repeatability rather than rapid price fluctuation.

Conclusion: Interpreting Cost Beyond the Price Quote

Understanding how much plastic injection molding costs in China requires looking beyond an initial quotation. Tooling precision, material behavior, production volume, and process stability all shape the final outcome. Companies engaged in China injection molding often achieve better results when cost is evaluated alongside engineering capability. By concentrating on precision molds, efficient processing, and structured overmolding applications, they help clients approach cost planning with clearer expectations. In this context, Livepoint Tooling represents a manufacturing partner whose methods emphasize consistency and technical alignment rather than short-term pricing assumptions.