Integrating advanced dimensional analysis into quality control processes requires specialized equipment. The Epic Eye Laser L from transfer3d addresses this need with a specific set of functionalities. This laser camera is engineered for precision, offering features that cater to environments where measurement accuracy is critical. The following sections detail the core attributes of the Epic Eye Laser L system.

High-Definition Laser Scanning Technology

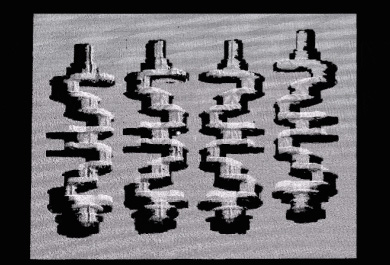

The core of the Epic Eye Laser L system is its advanced laser projection unit. This component captures surface data with a high point density, creating detailed point clouds. This capability allows the laser camera to document complex geometries and minute surface variations that are often missed by conventional measurement techniques. The technology provides a foundation for accurate digital replication.

Structured Light Processing for Data Integrity

Beyond the laser itself, the unit employs sophisticated structured light processing. This method involves projecting a pattern onto the target and analyzing its deformation. The system’s algorithms interpret these distortions to calculate precise spatial coordinates. This process ensures the data collected by the Epic Eye Laser L maintains high fidelity, which is necessary for reliable inspection and reverse engineering tasks.

Seamless Integration with Digital Workflows

A key feature of the transfer3d ecosystem is interoperability. The data output from the Epic Eye Laser L is designed for direct import into common CAD and metrology software platforms. This eliminates cumbersome data conversion steps and preserves measurement integrity. This integration streamlines the path from physical object analysis to a usable digital model, enhancing project efficiency.

The feature set of the Epic Eye Laser L positions it as a practical tool for industrial metrology. Its combination of detailed data capture, robust processing, and software compatibility supports quality assurance and product development cycles. For organizations utilizing transfer3d technology, these attributes facilitate a more data-driven and precise approach to manufacturing and inspection.